Early followers of this blog may be familiar with several projects to 3D print kiteboard and stand up paddle (SUP) board fins, including some fins you can freely download if you’re into kitesurfing. It’s been a little while between posts on this topic, however, I have been busy in the background producing a system to help people with no CAD experience design and customise their own fins ready for 3D printing. The full details have just been published in the Computer-Aided Design and Applications Journal.

Quite a few people have used 3D printing to produce surf fins – after all, it’s very cheap and means you can produce just about any geometry you like. Researchers have looked at the strength of different materials and 3D printing technologies for this application, as well as the performance (fluid dynamics) of different geometries. However, if you are not a relatively advanced CAD user, it is unlikely you will be able to design the fin of your dreams, no matter how awesome the research suggests 3D printing can be! This is what I was interested in solving.

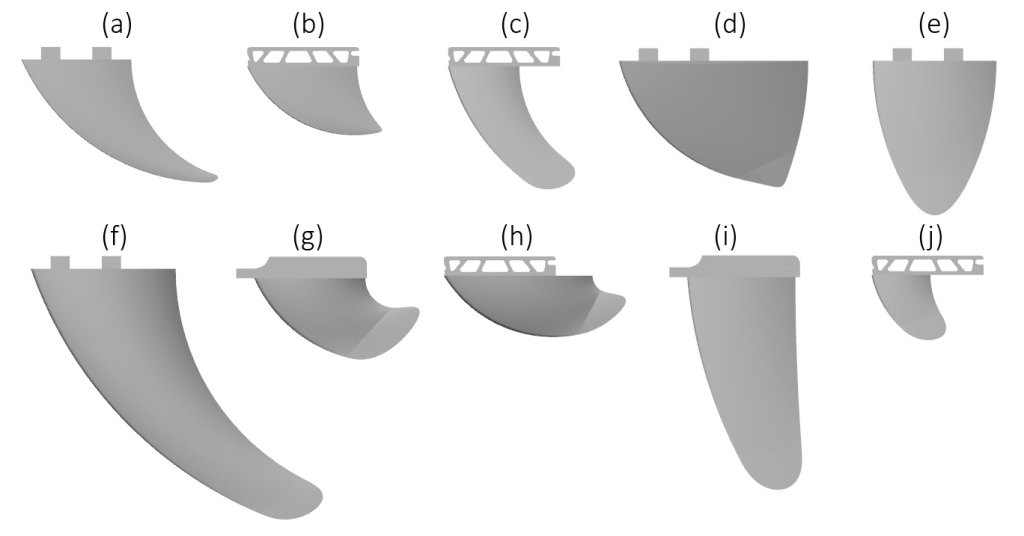

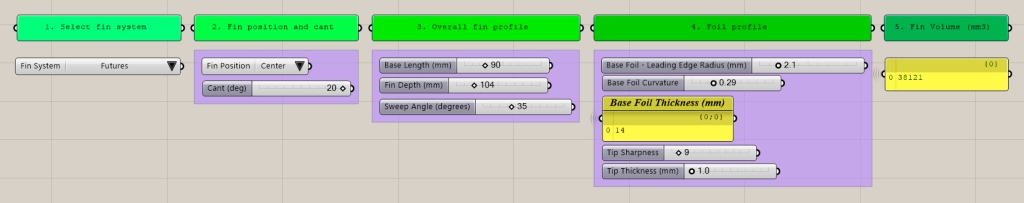

Using Rhinoceros and Grasshopper, the complexity of a fin was condensed down to a series of limited controls that allowed for freeform experimentation. The above image is the interface that allows surfers to customise a fin design in real-time. It is based on a handful of common fin properties such as the fin system, fin position on the board, cant, fin depth, sweep, base length, base foil profile, tip sharpness and tip thickness, all of which can be modified using some simple sliders or dropdown menus. Feedback is also provided in the form of overall dimensions and volume. From the image at the top of the page, you can get a sense for the wide variation in designs possible from this simple interface.

Once you’re happy with the design it can be exported ready for 3D printing. I’ve 3D printed a couple of different designs for testing on my SUP board, the smaller white fin in the image above being 3D printed using FDM, while the larger fin was 3D printed using selective laser sintering (SLS). Both worked well in flat water paddling, although I’m sure some carbon fibre would give me a bit more confidence heading into the surf.

Hopefully some more to come soon as spring and summer approach.

– Posted by James Novak