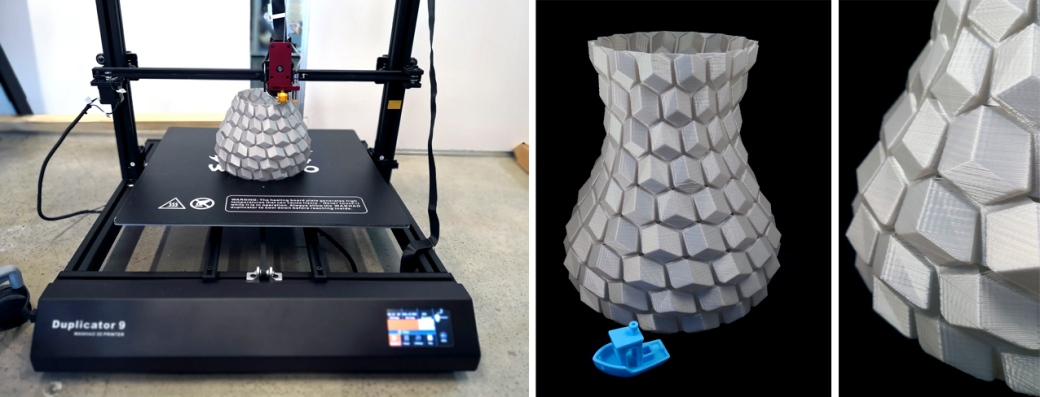

If you have followed my blog for any length of time, you’ve probably noticed I’m quite a big fan of the Wanhao 3D printers – they’re cheap, reliable, upgradable, and just good value for money. Even my Cocoon Create from Aldi is actually just a Wanhao in disguise! Recently Wanhao released the Duplicator D9/500, which has an incredible 500x500x500mm build volume. Yes, you read that right, those numbers are not a typo! The picture above doesn’t do it justice, this is a big unit that currently we can only store and run on the floor until we can free up a large desk. Manoeuvring this thing is definitely a 2 person job!

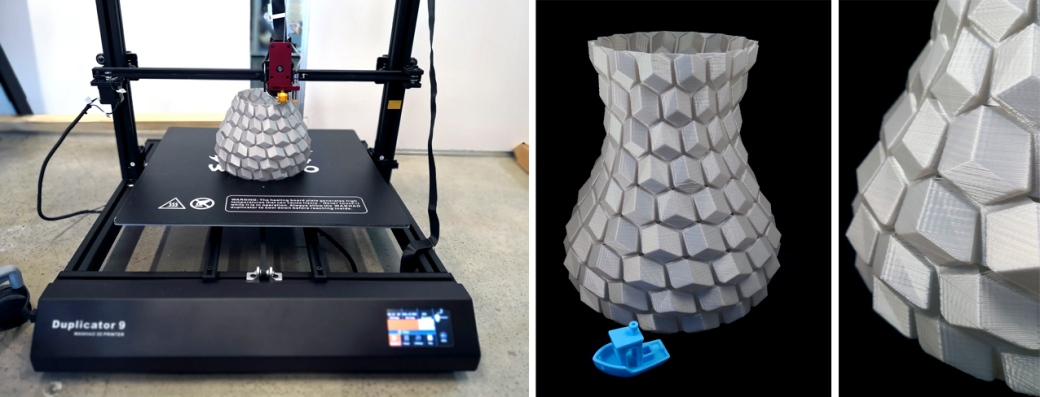

Before I get into the details of the machine and my first experiences, the printed vase pictured above is the first successful print, which is the Curved Honeycomb Vase (free on Thingiverse) printed at 200% scale. Printed in vase mode (aka “spiralise” in Cura) with a 0.8mm nozzle, this print took approximately 6 hours to complete. A great design in itself, and very cool at this large size.

However, it certainly hasn’t all been smooth sailing with this printer. First, there were some lengthy delays from Wanhao between when we placed the order and finally received the machine – apparently some manufacturing and quality control issues, and Wanhao may have released the machine a bit too early to market. In total we waited several months, however, they may be much faster now that issues seem to be resolved. The second big issue we faced was assembly – the supplied instructions weren’t particularly useful or even relevant, with some of the components no longer supplied with the printer – it seems that the initial release included large brackets to help stabilise the frame and some other details in the instructions, so we were left feeling like we were missing some parts. Apparently we are not, although we still haven’t figured out some of the cable management issues and have had to hack together a temporary solution for now.

Another challenge with assembly was in constructing the frame; obviously at such a large size the frame wasn’t pre-assembled like the smaller Duplicator 3, and the frame also uses extruded aluminium rather than folded sheet metal. Squaring all of these extrusions is not simple, and some initial issues when running the machine were related to having one of the vertical frame pieces lightly twisted. Some better alignment details are definitely needed.

The final issue that we’ve been experiencing is in the auto-levelling sensor, which was not installed at the correct height in the factory and required a lot of manual adjustment (we had the nozzle collide with the bed several times when first running it). However, even with this, the machine doesn’t really seem to adjust the prints for any levelling issues; our first prints across the bed revealed a number of areas where the bed was slightly warped, which were not being corrected by the auto-level feature, so we are currently manually doing adjustments for now. And we have found the central area of the bed is OK, so the vase printed really well.

So overall I would have to recommend that anyone considering this printer hold off for at least a few more months, there are just too many issues for anyone without a lot of experience calibrating 3D printers, and without the time to really get in and troubleshoot issues. Last time I searched on YouTube it seems others have also come to a similar conclusion. I think with time this will be a great 3D printer, we’re certainly going to keep learning more about it, but this seems like a case of a manufacturer rushing to market without properly testing and perfecting their equipment. Unfortunately, an all too common story in the 3D printing world.

Make sure you follow my blog and social media accounts to keep up to date with ongoing test prints and posts about the Wanhao Duplicator D9/500. And please share your own experiences in the comments section so we can all learn from each other 🙂

– Posted by James Novak

*UPDATE 14/1/2019 Recently I have updated the firmware of the printer to see if that would improve performance of the machine. I recommend this as a priority for anyone with a D9, it could fix some of the issues you may be experiencing as there are probably several different versions of firmware out there now depending when you purchased your printer. While I haven’t noticed a difference with the levelling issues, it’s always worth running the latest firmware to fix any other potential issues. This video tutorial is excellent, I followed it exactly and managed to update both the LCD display and motherboard to version 0.164(B).

For now I’ve manually adjusted the levelling sensor so that in some areas the nozzle is lower than it should be, pushing into the print surface. This makes other areas of the warped plate the correct height, and after a few layers seems to level things off and be printing OK. Not great, but working for now.

It’s certainly not something needed for every print, but for large surfaces it’s proving to be very successful. If you’ve had similar problems with warping and haven’t tried a brim yet, it’s worth giving a go – you can see where to access this setting if you are using

It’s certainly not something needed for every print, but for large surfaces it’s proving to be very successful. If you’ve had similar problems with warping and haven’t tried a brim yet, it’s worth giving a go – you can see where to access this setting if you are using